Liftgate related injuries, unfortunately, are ever-present in today’s transportation industry. However, you can minimize room for error and the risk for injuries when you practice routine equipment maintenance, utilize proper handling, and operate with the recommended safety practices. Here are some safety practices you should abide by when operating your liftgate:

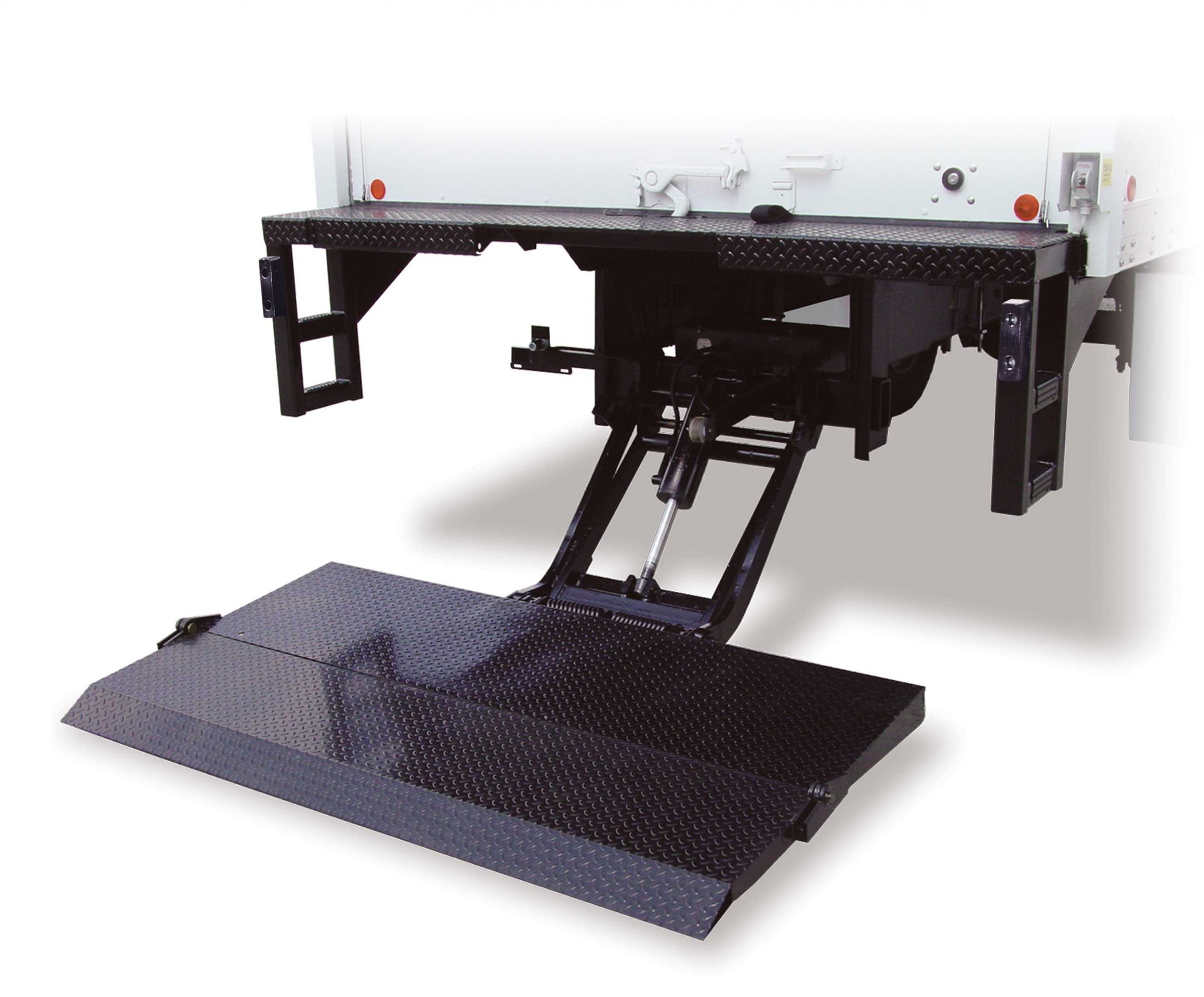

Learn about the specific type of liftgate you’re dealing with.

There are many varieties of liftgates. As a responsible operator you should read the manual before you use it, even if you’ve handled similar machinery in the past. Take your time in reading the manual and learn about all the hazards associated with your lift.

You should locate all of the safety decals and follow the instructions strictly. See to it that the weight of your cargo does not exceed your liftgate’s capacity.

Perform checks prior to use.

As is the protocol for operating any type of equipment, you should first perform a thorough check on your machinery before using. Check for signs of damage and abuse. Do not use if you’re unsure of the state of your liftgate.

Contact a liftgate mechanic to support the initial check you made on the equipment. Your liftgate might require adjustment, new parts, or replacement, depending on the findings of your local mechanic.

Never exceed load and lift capacity.

Clearly calculate the weight of your load and the capacity of your liftgate. Never overload. Overloading is the easiest way to damage your equipment. Not only will this increase the risk of your liftgate failing, but it can also damage your cargo and hurt any bystanders in the event of an accident.

Keep your body away from pinch points.

A pinch point is anywhere you could get caught within the moving parts of a machine. Hands and feet are particularly vulnerable during the lowering and raising of the lift gate. Keep your body parts clear of all pinch points. Never enter the area beneath a raised lift!

Conduct routine equipment maintenance.

An easy way to ensure your equipment continues to function properly is to have professionals conduct routine maintenance. Doing so allows liftgate mechanics to check for leaks and any potential damage to the equipment that could lead to an accident later on. Simply checking your equipment and bringing it to a service center is enough to ensure overall long term operational quality. Never repair the liftgate yourself!

Contact a liftgate mechanic to facilitate replacement if the equipment is beyond repair.

For all your liftgate repair, replacement, or maintenance needs in Oklahoma, contact Truck-N-Trailer Service. Call (405) 912-5800 today! www.oktruckrepair.com