Brakes are the single most important safety feature on any vehicle. They are the primary defense to try and avoid vehicle to vehicle collisions & vehicle/property accidents that can lead to vehicle occupant or innocent bystander injuries. As a truck operator or owner, you must give priority to your vehicle’s entire brake system by making it a top priority of your scheduled maintenance tasks.

Brake problems are typically not difficult to identify if you know the signs. Catching the symptoms early will allow you to address issues before they escalate into an expensive problem. Here are some common ways to know if your truck has an impending brake problem:

Brake Balance Problems

Ideally, each rear wheel of your truck does their part in the vehicle’s braking work. Both wheels are expected to provide the same force to bring the vehicle to a stop.

If you are driving your truck and you notice that it is pulling distinctly to the right or left, there is certainly an underlying problem that needs to be addressed. Assuming that your trucks tires are properly balanced and its adjustments are correct, the problem could be caused by any of these factors:

- Mismatched pad or shoe lining material

- Glazed inner surface of the drum

- Plugged hydraulic brake lines from debris contamination in system (such as rust or dirt)

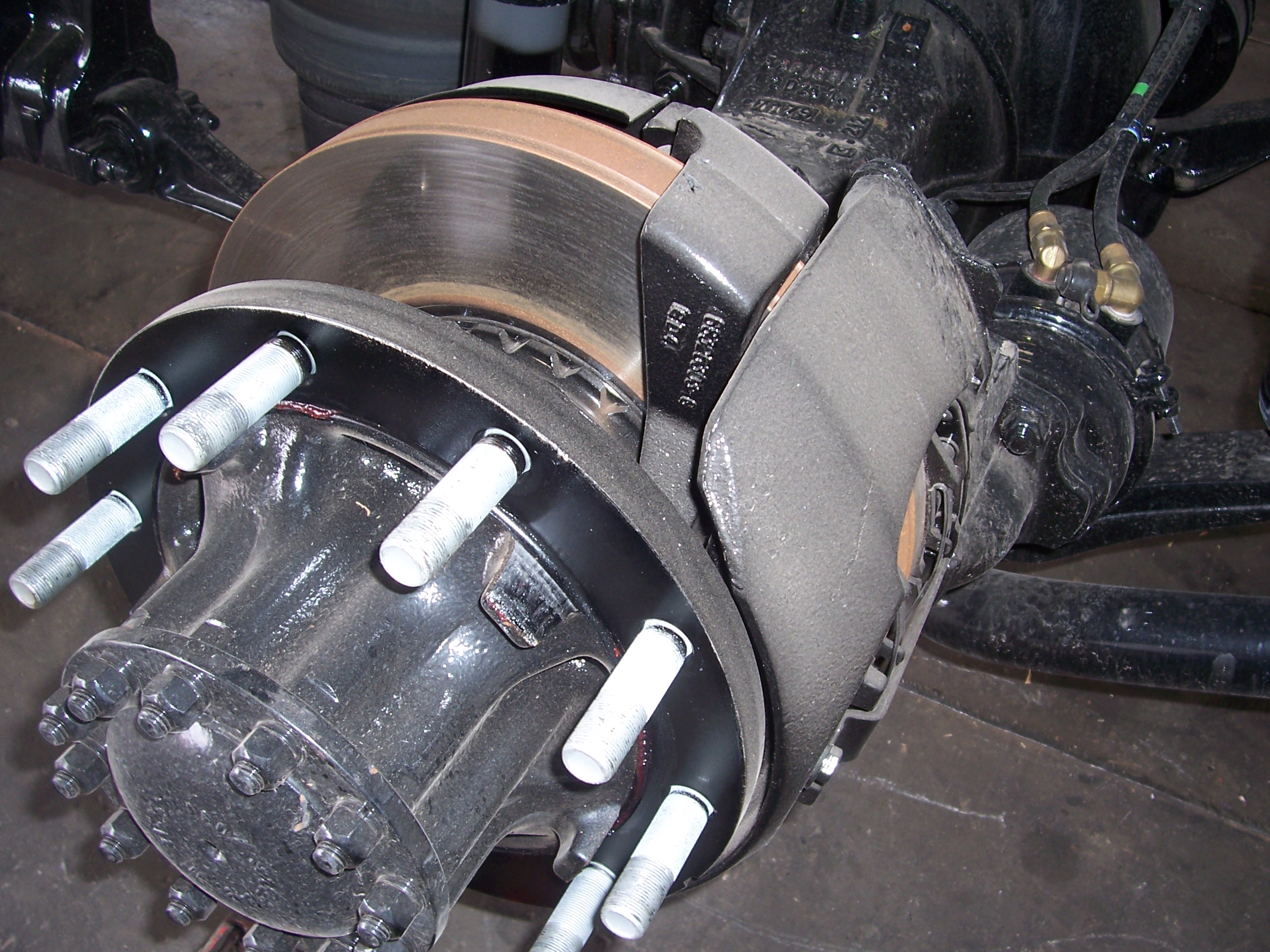

- Seized or leaking disc brake caliper or one of its’ components

- Seized or leaking drum brake wheel cylinder

- Mismatched air hoses and fittings between valves and brake chambers (Air Brake systems)

- Air Supply hoses have a larger or smaller inner diameter than the opposing air line.

- Wrong sized slack adjuster or brake actuator chamber

- Twisted or kinked air supply hose

- Defective brake mounting foundation that causes hardware to deflect when brake is applied

Some brake problems are easy to detect via a visual inspection especially if some parts are broken or damaged. But if the problem is internal, it can be a bit more difficult to diagnose. For this reason, you should seek the help of a professional and qualified truck service provider; like the medium duty truck service center at Truck N Trailer to do an in depth diagnostic brake check to discover the issue and provide the correct repair solution.

You can simplify your service provider’s job by pointing out specific symptoms such as: which side your truck pulls to, at what speed, were the brakes applied or not when truck pulled a certain direction, the amount of payload, or type of road surface.

Timing Problems

A truck’s brake system requires two important elements in order to work effectively – balance and timing. Even advanced safety features such as the anti-lock braking system (ABS) or electronic stability control can’t do much to prevent accidents if your brakes do not respond as they should.

This is especially true with large tractor-trailer brakes which are designed to apply and release in proper order, with the trailer first. If the tractor brakes apply first or with greater force, the trailer can continue to move triggering stability problems. On the other hand, trailer brakes that apply first but fail to release as expected will trigger a skid. If the timing is not correct when you apply your brakes on your medium duty or larger truck, you should consult a competent truck repair shop immediately.

Brake failure can be prevented. If you discover a problem, solving or repairing yourself in many cases may be beyond your capability. To ensure the safe operation of your trucks, seek the help of certified professionals at a reputable truck repair shop.

Ensure the safety, roadworthiness and efficient performance of your fleet. You can rely on the skills, experience and reliability of the service technicians at Truck N Trailer.

Call us at (405) 912-5800 and ask for our experienced Service Manager Kirk Booth to discuss your truck service needs.